Table of Contents[Hide][Show]

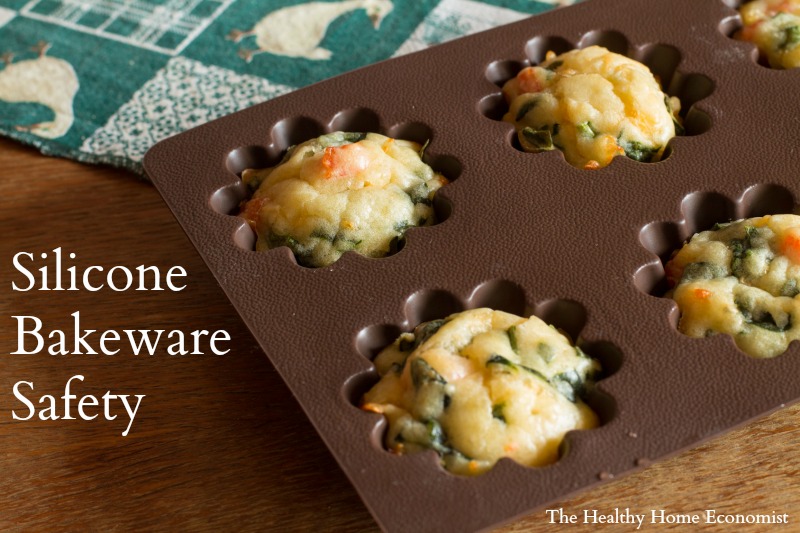

How to safely use silicone bakeware and other types of molds in your home and identify nontoxic brands that are worth your hard-earned dollars!

As a follow-up to the recent article on using stainless steel cookware safely in your kitchen endeavors, this article explores the use of the very attractive silicone molds (also spelled moulds) for baking and cooking.

Silicone bakeware and kitchenware have skyrocketed in popularity due to growing consumer awareness about the health dangers of aluminum and Teflon.

Ironically, this switcheroo appears to be unwise for those seeking a nontoxic baking experience. While aluminum bakeware can actually be safely used under certain circumstances, it appears that it is best to avoid silicon molds in most cases. There are some welcome exceptions to this recommendation, however, for those of you who already own some.

Silicone vs Silicon

What exactly is silicone anyway? Is it the same thing as silicon, the natural element with the chemical symbol Si and atomic number 14?

Silicone and silicon are actually quite different, but the fact that silicon is a natural element is likely what confuses consumers to the profitable advantage of kitchenware manufacturers.

According to Scientific American, silicone is a synthetic rubber:

Silicone, a synthetic rubber made of bonded silicon (a natural element abundant in sand and rock) and oxygen, is increasingly filling this niche. The flexible yet strong material, which has proven popular in muffin pans, cupcake liners, spatulas and other utensils, can go from freezer to oven (up to 428 degrees Fahrenheit), is non-stick and stain-resistant, and unlike conventional cookware, comes in a range of bright and cheery colors. (1)

Silicone Widely Considered to be a Safe Kitchenware Material

If you check out manufacturer claims, health blogs, and related websites, most give glowing reviews of silicone.

Silicone rubber is inert. It does not emit fumes of any sort, leech into food, or pose any health risks according to the FDA. Experts consider it non-reactive and a good choice when looking for low-risk cookware. (2)

Digging into the research reveals a very different picture. Researchers and their published studies on the subject do not seem to agree at all that silicone is safe. The concerns stem primarily from the newness of silicone molds for cooking and baking for which there is little research to date.

This is surprising because in 1979 the U.S. Food and Drug Administration (FDA) gave the thumbs up to silicon dioxides. This approval was formally granted by awarding coveted GRAS status (Generally Recognized As Safe) upon these basic elements in silicone cookware and bakeware. (3)

Cookbook author and food columnist Marian Barros put her concerns about silicone this way:

One question nagged at me as I put these [silicone] tools through their paces: Is this stuff safe? Unfortunately, there is not as much research as I had hoped. (4)

Primary Safety Concerns

With silicone cookware and bakeware, there are three main areas of concern:

- Materials used to make the silicone molds.

- Molding and tempering agents used in manufacturing.

- Potential for migration of these materials into food.

Let’s look at each in turn.

Materials used

A big problem with any product that becomes popular is cheap, low-quality alternatives.

Silicone is no different. Many of the reports about off-odors and other issues with silicone bakeware seem to come from low-quality products containing cheap dyes or fillers.

The “Twist” Test

The “twist” test is an easy way to assess the quality of a silicone cookware item. All you have to do is take a silicone product in your hands and twist it. If lots of white streaks appear, it indicates the presence of a large number of fillers. Pure silicone (safer) will hold its color when twisted. (5)

It is also best to make sure any silicone items you own are made from 100% pure food-grade silicone. If the label or store does not guarantee as much, contact the manufacturer. Another option is to work only with companies that do guarantee the purity of their products. (6)

Molding Agents

To get products to easily release from high temperature and pressure molds, manufacturers utilize various compounds/agents to coat silicone products.

For food-grade items, this means using only specific food-approved agents.

Even then, some may adhere to the final product. The one major study on silicone cookware published by the Swiss Federal Office of Public Health in 2005 supports this assertion.

The high weight loss in the first heating cycle is most likely due to residual solvents and/or by-products formed during the manufacture of the articles or due to the fact that the time for the postcuring of the article was not sufficient. This process is easy but requires much energy.

To avoid additional expenses, some firms leave out this last stage and ask their customers to heat the mould at 230 °C (446 °F) during 2 h without food before the first use, stating that the possible development of some smoke is not deleterious. (7)

You also have to wonder …. how many consumers actually read the directions and heat the mold (if required) for 2 hours in the oven at the appropriate temperature before using it with food? Best guess? Not many.

After that, wash silicone molds thoroughly with warm water and soap and then rinse completely. It is not advisable to put them in the dishwasher for the reasons outlined below.

Migration of Silicone into Food

The biggest concern with any cookware is whether it harms us biologically if any is ingested. A lot of websites and blogs tout the safety and inertness of silicone kitchenware molds, but it appears the assumptions may be overhyped into “fact”.

The one large study on silicone molds used for cooking purposes mentioned earlier examined this very thing:

The objective of this work was to study the release of chemical substances from the silicone baking moulds at various temperature, especially around 200–220°C, temperatures attained in an oven when cakes and pastries are baked. Some tests at higher temperatures up to 280°C were also performed to check the statement of the manufacturers concerning the heat stability of the moulds. The tests currently specified for migration for food contact applications involve temperatures not exceeding 175°C. It is thus very important to develop migration procedures that make possible the investigation in a real temperature range. (7)

What was discovered was disconcerting, to say the least:

Even though silicone elastomers demonstrate a high degree of thermal stability and excellent resistance to aging, high temperatures lead to depolymerization of the elastomer, with subsequent volatilization and migration [into food] of certain substances. The few publications concerning the suitability of silicones as food contact materials have indeed shown that a certain quantity of substances migrates from silicone-based articles. (7, 8)

Tempered vs Non-tempered

How much material ends up in food during use?

Lots!

Tempering or strengthening the hardness and elasticity of the silicone had a major influence on the migration properties of silicone polymers (siloxanes) into various foods tested.

Non-tempered molds containing a high level of volatile organic compounds (1.1%) were shown to have considerably higher migration into food than the equivalent tempered molds. (9)

What about other silicone products?

The last nail in the silicone coffin is the numerous studies on silicone products in other applications. This includes medical devices that are implanted inside the body.

Usage studies have shown leeching and similar problems with subsequent deleterious health effects. You can check out a good article with many more links to further research here. (10)

Is Silicone Bakeware Ever a Good Idea?

It seems wise based on current research on silicone molds to avoid them in cooking applications.

Obviously, those popular silicone muffin cups and pans should never be utilized in a hot oven! For stirring hot dishes and soups, metal, wood, and bamboo utensils are preferable to those made with silicone.

Silicone spatulas or similar utensils to scrape out bowls and other containers are fine to use once the food has cooled.

Also, once post-cured in the oven (if suggested by the manufacturer) and thoroughly hand-washed, it is fine to use silicone-based molds for making ice cubes, jellies, popsicles, and other similar items in the refrigerator or freezer.

Just remember to hand wash in warm water and mild soap after use. This avoids leeching risks from the harsh detergents and hot water of the dishwasher.

Of course, the nonfood use of silicone molds is of little concern. A lot of people use them to enhance the ease of soap and candle-making projects. Such usage poses no health risks.

In summary, silicone molds for nonfood purposes are safe.

For use in heated food applications, always avoid.

For use at room temperature, refrigerated or freezing applications, silicone molds pose no risk according to current research.

May I ask what materials you suggest using in flexible spatulas, basting brushes, and egg whisks? I used these often when handling hot food.

What about silicone teethers for babies? They are sold as “non toxic”

Personally, I wouldn’t buy them.

What about Silpats?

Thank you

Haven’t looked at those specifically, but as with anything made of silicon, cold temperature use only. Never bake or otherwise heat food in them.

I found a study that said low molecular weight siloxanes do enter skin, and they volatilize or enter the air for breathing. The study you referenced said that heat generates new low molecular weight particles in the silicone molds and that oils become partly trapped in the molds especially at higher heat, eventually becoming rancid and leaking out for contaminating new batches of soap or food. If the soap batter is already cool enough, does not heat up again much during saponification, and if the mold is not used long-term, silicone might be okay for soap making. Alternatively, parchment paper and freezer paper, both coated in silicone, might be better throw-away options to solve the rancidity problem, and it seems to me that there’s less silicone with which oils can interact. Waxed paper has been said by some to work well if the wax is faxing away from the soap. The only non-silicone options seem to be wood or metal boxes (perhaps with hinges) and no paper as a liner, knowing that it will be tough to remove the soap from the mold and get them clean for the next batch. Cutting imperfections off of potentially more than one side of the log/block might be something to expect.